Product Description

Our conveyor rollers have been exported to more than 30 countries all over the world in past 34 years and we have professional engineers and all of them have rich experience in this field, we can design the goods independently.

Standard: GB, ISO, CEMA, DIN, JIS, etc

Production capacity: As usual 5000 pieces/ week, but urgent order is acceptable

Certificate: CE, ISO, BV, SGS, IKA, etc

Advantage:

The life time: More than 30000 hours

Samples for testing are available.

The more relaxed payment terms

Detailed conveyor roller idler feature:

1. Roller idlers Dia 50mm-219mm, length 190-3400mm, which are used in the steel industry, harbor, coal industry, power industry, cement industry, etc

2. Tube: Q235

3. Shaft: 45# STEEL

5. Bearing: Single & Double Row Deep Groove Ball Bearing 2RZ&2Z with C3 clearance.

6. Seals: Grease retaining inner seal with Multi-stage Labyrinth and Retention Cap with Outboard Rubbing Flinger Seal.

7. Lubrication: Grease is Lithium soap type grease with Rust Inhibitors.

8. Welding: Mixed gas shielded arc welding end

9. Painting: Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting

Besides we can manufacture the rollers and idlers according to the buyers' requirements

| Standard External Diameter |

Standard Inner Diameter |

Length scope ( mm) | Bearings Type (Min~Max) |

|

| mm | In | mm | ||

| 89 | 3 1/3 | 60/50 | 170-3400 | 204 |

| 102 | 4 | 76 | 170-3400 | 204 205 |

| 108 | 4 1/4 | 89/76/60 | 170-3400 | 204 205 |

| 114 | 4 1/2 | 89/76 | 170-3400 | 204 205 |

| 127 | 5 | 89 | 170-3400 | 204 205 |

| 133 | 5 1/4 | 89/70/63.5 | 170-3400 | 204 205 |

| 140 | 5 1/2 | 89 | 170-3400 | 204 205 |

| 152 | 6 | 108/76 | 170-3400 | 306 |

| 159 | 6 1/4 | 108 | 170-3400 | 306 |

| 194 | 7 5/8 | 159/133 | 170-3400 | |

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Grooved Conveyor Idler |

| Certificate: | CE, ISO, BV, SGS, Ika, etc |

| Customization: |

Available

|

|

|---|

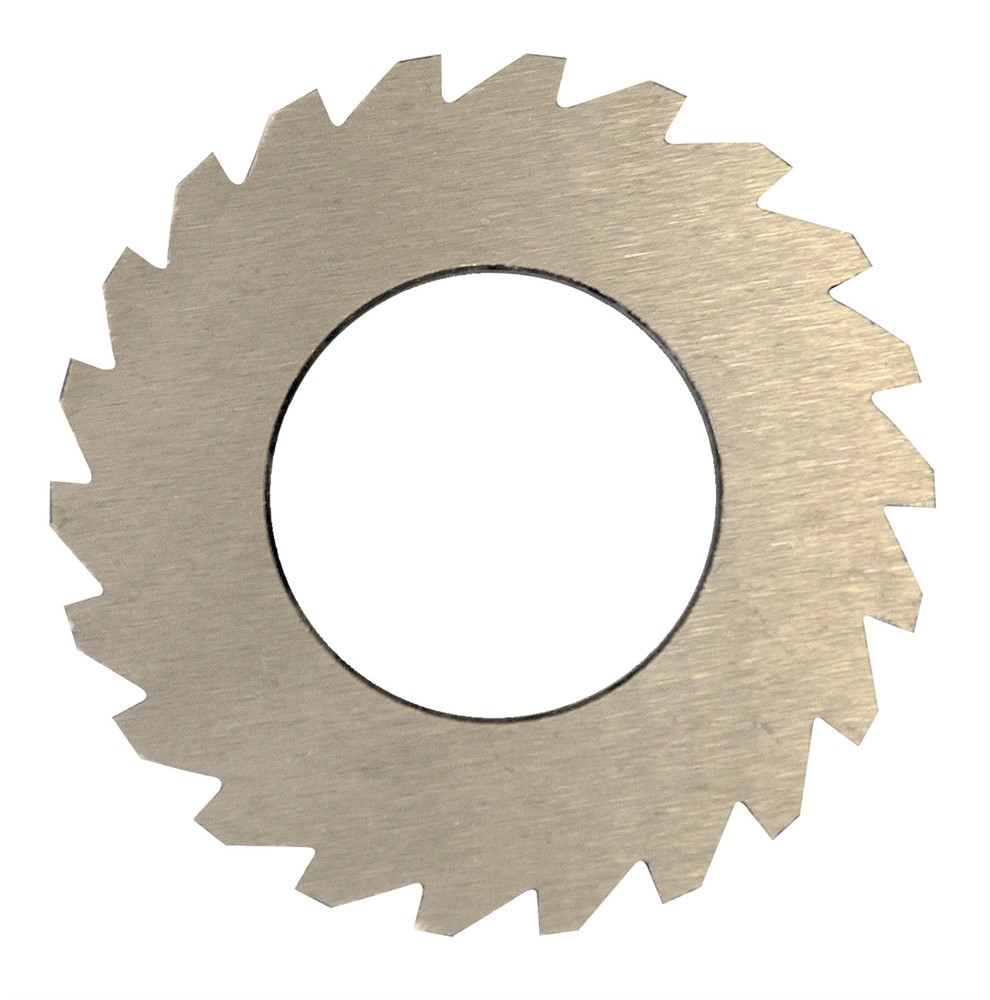

Can ratchet wheels be customized for specific uses or integrated into different systems?

Yes, ratchet wheels can be customized for specific uses and seamlessly integrated into various mechanical systems. Customization allows for tailoring ratchet wheels to meet the unique requirements of specific applications. Here are ways in which ratchet wheels can be customized and integrated:

- 1. Custom Tooth Profile: Ratchet wheels can be designed with a specific tooth profile to match the desired level of control and movement. Custom tooth spacing and sizes can be created to achieve precise incremental motion or accommodate varying load capacities.

- 2. Material Selection: Depending on the application's demands, ratchet wheels can be manufactured from different materials, including various types of metals such as steel, stainless steel, or alloys. Specialized coatings can also be applied for enhanced durability and corrosion resistance.

- 3. Size and Diameter: The size and diameter of the ratchet wheel can be customized to fit within the available space of the mechanical system. This ensures a proper fit without clearance issues or interference with other components.

- 4. Load Capacity: Custom ratchet wheels can be designed to handle specific load capacities, making them suitable for both light-duty and heavy-duty applications. Reinforced designs with larger teeth and diameters can support heavier loads.

- 5. Pawl and Catch Mechanism: The design of the pawl or catch mechanism can be tailored to ensure optimal engagement and disengagement with the custom ratchet wheel. This customization ensures reliable operation in the intended application.

- 6. Precision Requirements: For applications demanding precise control and adjustments, fine-tooth custom ratchet wheels can be created to provide finer incremental movement and enhanced accuracy.

- 7. Regulatory Compliance: Custom ratchet wheels can be designed to meet specific industry standards and safety regulations, ensuring compliance with applicable requirements.

- 8. Integration into Systems: Ratchet wheels can be seamlessly integrated into various systems, including hand tools, winches, tie-down mechanisms, conveyor systems, and more. Their unidirectional and locking capabilities make them valuable components in many applications.

Customized ratchet wheels are often used in specialized industries and applications where standard off-the-shelf components may not fully meet the unique demands. Manufacturers and engineers work closely to design and produce custom ratchet wheels that precisely match the specifications and requirements of the intended use, contributing to the efficiency and reliability of the mechanical systems they are part of.

What safety considerations should be taken into account when using ratchet wheels in various settings?

When using ratchet wheels in various settings, it is crucial to prioritize safety to prevent accidents and ensure the well-being of operators. Here are essential safety considerations to keep in mind:

- 1. Proper Installation and Alignment: Ensure that ratchet wheels are correctly installed and aligned with their accompanying pawls or catches. Misalignment or improper installation can lead to unreliable operation and safety hazards.

- 2. Regular Inspection and Maintenance: Implement a routine inspection and maintenance schedule for ratchet wheels and their associated components. Look for signs of wear, damage, or misalignment, and address issues promptly to prevent accidents.

- 3. Load Capacity: Adhere to the specified load capacity of the ratchet wheel and the entire system. Overloading can cause failures, leading to dangerous situations. Always consider the maximum load when selecting and using ratchet wheels.

- 4. Operator Training: Ensure that operators are adequately trained in the safe use of ratchet wheel systems. Training should cover proper operation, load limits, and safety procedures in case of emergencies.

- 5. Emergency Stop Mechanisms: In applications where ratchet wheels are used as safety interlocks or emergency stop devices, ensure that these mechanisms are reliable and regularly tested. In emergencies, they should halt operations immediately and effectively.

- 6. Lockout/Tagout Procedures: Develop and implement lockout/tagout procedures when working on equipment that includes ratchet wheels. This ensures that machinery is de-energized and cannot be inadvertently started during maintenance or repair activities.

- 7. PPE (Personal Protective Equipment): Provide and require the use of appropriate personal protective equipment, such as gloves and safety glasses, when working with or near ratchet wheel systems. PPE can reduce the risk of injuries in case of accidents.

- 8. Hazard Identification: Identify potential hazards associated with the use of ratchet wheels, including pinch points, sharp edges, and moving parts. Implement guards and warning signs to minimize risks.

- 9. Environmental Conditions: Consider the environmental conditions in which ratchet wheels are used. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized equipment and safety precautions.

- 10. Regular Testing and Certification: Periodically test and certify the safety mechanisms and components associated with ratchet wheels. This ensures that they meet industry standards and function as intended.

- 11. Risk Assessment: Conduct a risk assessment specific to the application of ratchet wheels. Identify potential risks and implement control measures to mitigate them effectively.

- 12. Compliance with Regulations: Be aware of and comply with relevant safety regulations, standards, and guidelines specific to your industry or region. Non-compliance can lead to legal and safety issues.

- 13. Emergency Response Plan: Develop an emergency response plan that outlines procedures for dealing with accidents or malfunctions involving ratchet wheel systems. Ensure that all personnel are familiar with this plan.

By incorporating these safety considerations into the use of ratchet wheels, you can help minimize risks, protect personnel, and ensure a safer working environment across various settings.

In what mechanical devices or tools are ratchet wheels commonly used, and how do they operate?

Ratchet wheels are commonly used in various mechanical devices and tools, where they play a crucial role in enabling unidirectional motion and preventing backward movement. Here are some examples of mechanical devices and tools that incorporate ratchet wheels and an explanation of how they operate:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, are widely used in automotive repair and mechanical work. They feature a ratchet wheel mechanism in the wrench head. When the user turns the handle in one direction, the ratchet wheel engages with the socket, allowing continuous rotation for fastening or loosening bolts or nuts. When the direction is reversed, the ratchet wheel disengages, preventing backward motion and allowing the user to reposition the wrench without removing it from the fastener.

- 2. Ratchet Straps and Tie-Downs: Ratchet straps and tie-downs are used for securing cargo on trucks, trailers, and in various transportation applications. They consist of a ratchet mechanism and a strap with hooks. By cranking the ratchet handle, the ratchet wheel tightens the strap, providing secure tension. The ratchet prevents the strap from unwinding or loosening during transit, ensuring that the load remains securely fastened.

- 3. Handbrakes in Vehicles: In automobiles, ratchet wheels are a fundamental component of handbrakes (parking brakes). When the handbrake lever is pulled, it engages a ratchet mechanism that locks the rear wheels in place, preventing the vehicle from rolling when parked on an incline. Releasing the handbrake disengages the ratchet, allowing normal wheel rotation.

- 4. Winches and Hoists: Winches and hoists used in industries such as construction, manufacturing, and material handling rely on ratchet wheel mechanisms. The ratchet wheel controls the winding and unwinding of cables or ropes. When the user operates the winch or hoist in one direction, the ratchet allows the cable to be pulled in and wound onto a drum. In the opposite direction, the ratchet prevents the cable from unwinding, ensuring controlled load handling.

- 5. Bike Gears: Bicycle gears often use ratchet mechanisms to control gear shifting. When a cyclist pedals forward, the ratchet wheel engages with the gear sprocket, allowing the chain to move smoothly and propel the bike. If the cyclist pedals backward or stops pedaling, the ratchet prevents the chain from moving in reverse, ensuring efficient pedaling and preventing the bike from rolling backward.

- 6. Fishing Reels: Many fishing reels, including spinning reels and baitcasting reels, incorporate ratchet mechanisms. The ratchet wheel in the reel allows the fishing line to be pulled in when the angler reels in a fish. The ratchet prevents the line from spooling out when there is no tension on it, ensuring that the line remains taut during fishing.

In each of these applications, the ratchet wheel functions by engaging with a pawl or catch mechanism. When force is applied in the desired direction, the pawl allows the ratchet wheel to rotate freely, enabling the intended motion. When force is applied in the opposite direction, the pawl engages with the teeth on the ratchet wheel, locking it in place and preventing backward movement. This simple yet effective mechanism provides controlled and safe operation in various mechanical devices and tools.

editor by CX 2023-12-12